Let me start by boasting: This is a soldering station that has both good looks and strength. It not only has a beautiful UI, but also has excellent temperature control performance. Author @createskyblue is named after the ancient god Suzaku.

1 Project features:

(1) The project uses ESP32PicoD4 main control, three-instrument amplifier circuit, and 1.3-inch SH1106 OLED screen.

ESP32PicoD4 is the best choice as a domestic chip with stable price, cheap performance and good performance.

The advantage of the three-meter amplifier circuit is that it has both high input impedance and low output impedance; the input stage is set to a higher amplification factor to amplify useful differential mode signals, while the gain of harmful common mode signals is 1 and common mode suppression The ratio is significantly improved, and the output stage is generally set to a lower magnification (within 2 times, usually designed to be 1 times), thereby significantly reducing the impact of resistor accuracy; only need to adjust the resistance of one resistor RG to adjust the total amplification magnification. Paired with Suzaku's excellent software, it's a perfect match. Thanks to the excellent architecture, ordinary operational amplifiers and ordinary precision resistors can be used without significantly reducing performance. It is simply a must-have tool for DIY. The instrumentation amplifier circuit can also be further replaced by a finished instrumentation amplifier chip, but the cost increases sharply.

1.3-inch OLED provides a larger screen display effect to a higher level

(2) The USB to serial port chip has also increased in price. Considering that the utilization rate of this part of the circuit is also low, it was removed and only the interface was reserved on the board. and buttons. When burning, just press and hold IO0 first and then press RES to enter BOOT mode to download the firmware.

(3). Based on the software, the rotation direction of the rotary encoder can be exchanged in the menu. In order to reduce one wiring crossover, pins A and B were exchanged.

(4). The thermocouple signal is separated and used for the JBC245 soldering iron tip compatible with three wires. Please refer to the schematic diagram for the wiring method.

(5). The welding positions of two QFN3X3 PMOS and two current sampling resistors are reserved for future use as a DIY reflow soldering heating station to improve the large current passing capacity.

(6).PCB matches aluminum alloy shell of 8838 specifications.

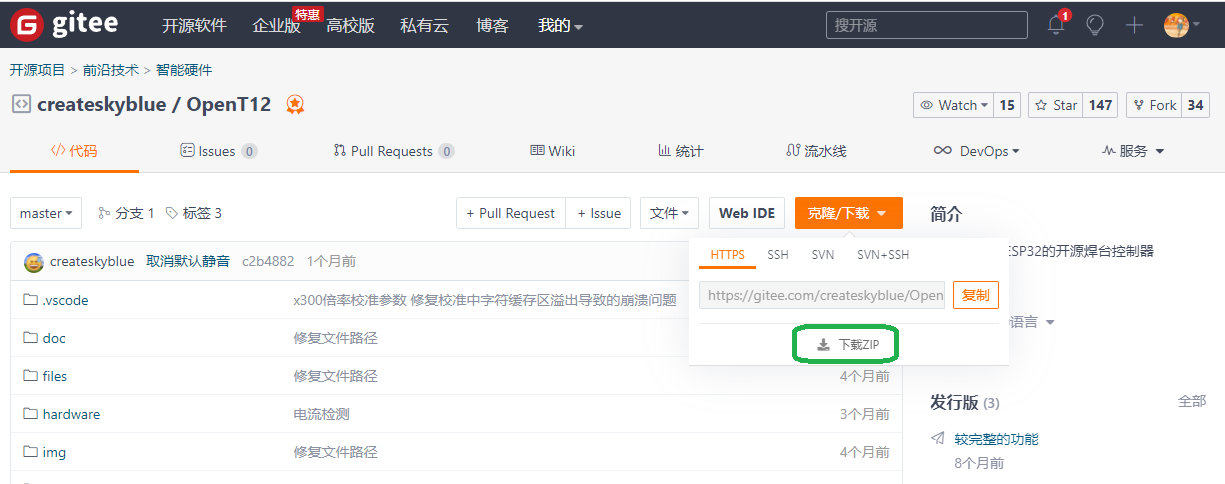

2. See gitee for the software, as shown in the picture below; I used Visual Studio Code to compile it; the software has not been changed, only I2C is enabled.

The activation method is as shown below. Modify the following two files to look like the picture.

It will not be modified, and there is no need to worry about the attachment. The compiled binary file is provided and can be burned directly (burning software and configuration pictures are attached).

3. This project is produced according to the modular idea. The following engineering packages are provided:

(1) Handle: supports two sleep schemes of vibration switch and reed switch: T12 handle bracket

(2) 8838 front and rear panels: 8838 front and rear panels

4. Version description: V1.3.4: Preliminary available, not found yet What's the BUG

V1.3.5: On the basis of 1.3.4, an antenna is added for wireless control functions that may be brought about by later software, and the line width of the power supply circuit is thickened.

5. Finished product display:

6. Credits: Suzaku T12 soldering station (replica version)

END

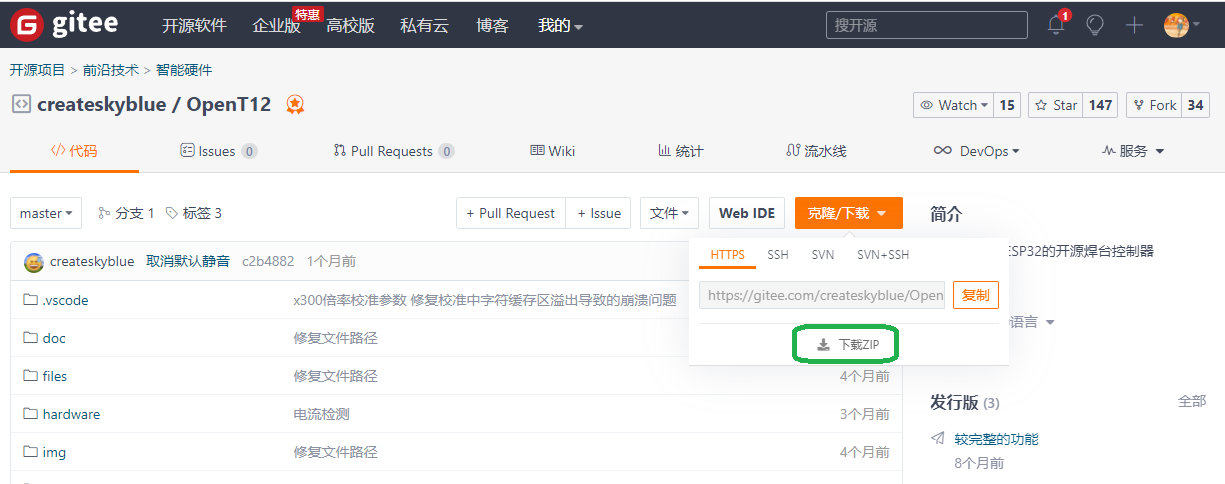

The activation method is as shown below. Modify the following two files to look like the picture.

The activation method is as shown below. Modify the following two files to look like the picture.