Does lithium iron phosphate battery need a protection board? The correct way to charge lithium iron phosphate battery

Source: InternetPublisher:偷熊计划 Keywords: Battery charging lithium iron phosphate battery battery protection board Updated: 2025/02/11

Do lithium iron phosphate batteries need a protection board?

Lithium iron phosphate batteries require a protection board. The protection board circuit can detect the voltage and current of each battery in the series battery pack and control the charge and discharge process of the battery pack. When the voltage of each battery in the battery pack is between the overcharge detection voltage and the over-discharge detection voltage, and there is no short circuit at the output, the MOS tube is turned on, and P+ and P- output the battery pack voltage, allowing the battery pack to be charged and discharged. In addition, the protection board also has functions such as battery pack over-discharge protection, overcharge protection, overcurrent protection, and short circuit protection.

How to properly charge lithium iron phosphate batteries

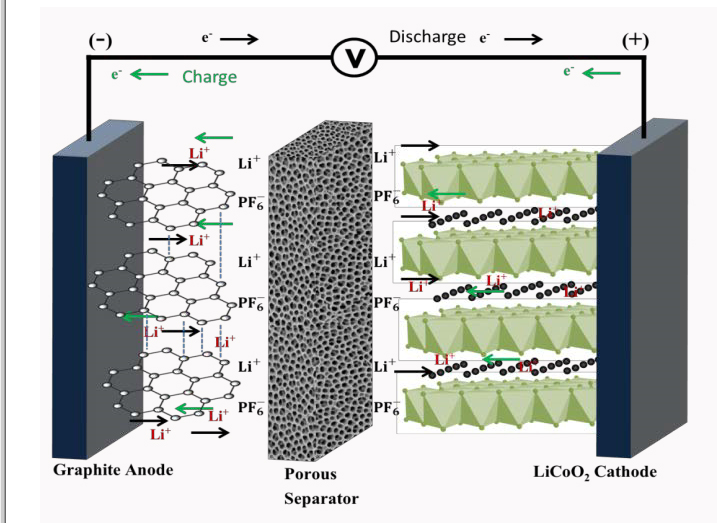

First we need to understand the structure and working principle of the lithium iron phosphate battery LiFePO4 as the positive electrode of the battery. It is connected by aluminum foil and the positive electrode of the battery. In the middle is a polymer separator, which separates the positive and negative electrodes, but lithium ions can pass through, but electrons cannot. The right side is composed of a carbon (graphite) battery negative electrode, which is connected to the negative electrode of the battery by copper foil. Between the upper and lower ends of the battery is the battery's electrolyte, which is enclosed in a metal casing. When the lithium iron phosphate battery is charged, the lithium ions in the positive electrode migrate to the negative electrode through the polymer separator. During the discharge process, the lithium ions in the negative electrode migrate to the positive electrode through the separator. Lithium-ion batteries are named after the lithium ions that migrate back and forth during charging and discharging.

When the battery is charging, lithium ions migrate from the surface of lithium iron phosphate crystals to the surface of the crystals. Under the action of the electric field force, they enter the electrolyte, pass through the diaphragm, and then reach the surface of the graphite crystal through the electrolyte, and then embed into the graphite lattice. At the same time, electrons flow through the conductor to the positive aluminum foil assembly electrode, through the pole ear, battery pole, external circuit, negative pole, negative electrode to the negative copper foil collection liquid, and then through the conductor to the graphite negative electrode, so that the negative electrode charge reaches balance. After the lithium ions are deintercalated from the lithium iron phosphate, the lithium iron phosphate is converted into iron phosphate.

When the battery is discharged, lithium ions flow out of the graphite crystal, enter the electrolyte, pass through the diaphragm, and then migrate to the surface of the lithium iron phosphate crystal through the electrolyte, and then re-embed the lithium phosphate in the lattice. At the same time, the battery flows to the negative electrode of the copper foil collecting electrode through the conductor, flows to the positive aluminum foil collecting liquid of the battery through the pole ear, the negative electrode column of the battery, the external circuit, the positive electrode column, and the positive ear, and then flows to the positive electrode of the lithium iron phosphate through the conductor, so that the positive charge reaches balance.

Note: Once again, lithium iron phosphate batteries should be waterproof and dustproof during use, so there should be no water in the storage area, which will affect the performance and service life of the battery.

It is recommended to use CCCV charging method, i.e. constant flow and constant voltage, for charging lithium iron phosphate battery packs. 0.3C is recommended for constant flow. 3.65 is recommended for constant voltage. That is, 0.3C current is used for constant current charging. When the battery voltage reaches 3.65V, it is charged at 3.65V constant voltage. When the charging current is lower than 0.1C (or 0.05C), charging is stopped, i.e. the battery is fully charged. When charging with a counterweight power supply, the charging current should also be considered. It is recommended not to charge with too high a voltage. Adjust the voltage to ensure that the charging current is below 0.5C, which is good for the battery.

Generally, the upper limit voltage of lithium phosphate battery charging is 3.7 to 4V, and the lower voltage of discharge is 2 to 2.5V. Taking into account the five aspects of discharge capacity, discharge medium voltage, charging time, constant current capacity percentage and safety, a constant current and constant voltage charging scheme is adopted for lithium iron phosphate battery packs. The charging limit voltage is set to 3.55 to 3.70V, the recommended value is 3.60 to 3.65V, and the lower limit voltage of discharge is 2.2V to 2.5V.

The charger for lithium phosphate battery pack is different from that for ordinary lithium battery. The maximum termination charging voltage of lithium battery is 4.2 volts, while that of lithium phosphate battery pack is 3.65 volts. The charging of lithium iron phosphate battery pack is a balanced charging board line, which is generally charged in series from both ends, and the charger voltage is greater than the battery pack voltage. The line detects the voltage of each unit core, which is equivalent to a side-by-side regulator. The single charging voltage does not exceed the regulation value, and other unit batteries continue to charge through the regulator bypass.

Because the power of each unit is close to full at this time, it is just balancing each single chip, so the charging current is very small, which supplements the balance of each core. The charger can only protect the end voltage of the entire battery pack. The balance charging board is to ensure that each unit is overcharged and each unit is fully charged. The entire lithium battery pack cannot stop charging because a charging cell is fully charged.

Charging method of lithium iron phosphate battery pack

(1) Constant voltage charging method

During the charging process, the output voltage of the charging power supply remains constant. As the charging state of the lithium iron phosphate battery pack changes, the charging current is automatically adjusted. If the specified constant voltage value is appropriate, it can not only ensure the full charging of the power battery, but also minimize degassing and water loss. This charging method only considers the change of the single state of the battery voltage and cannot effectively reflect the overall charging condition of the battery. Its starting charging current is too large, which often causes damage to the power battery. Due to this shortcoming, constant voltage charging is rarely used.

(2) Constant current charging method

The charging current is kept constant by adjusting the output voltage during the entire charging process. Keeping the charging current constant, the charging rate is relatively low. The constant current charging control method is simple, but because the acceptable current capacity of the lithium battery pack gradually decreases during the charging process, the power capacity of the power battery decreases in the later stage of charging, and the charging current utilization rate is greatly reduced. The advantages of this method are simple operation, convenience, easy implementation, and easy calculation of charging power.

(3) Constant current and constant voltage charging method

This charging method is a simple combination of the above two. The first stage uses constant current charging to avoid the charging current at the beginning of constant voltage charging. The second stage uses constant voltage charging to avoid overcharging during constant current charging. Lithium iron phosphate battery packs, like any other sealed rechargeable batteries, should be charged in a controlled manner and should not be overcharged, otherwise it is easy to damage the battery. Lithium iron phosphate batteries generally use a charging method of constant current first and then voltage limiting.

(4) Chopper charging method

The chopper method is used for charging. In this method, the current of the constant current source remains unchanged, and the switch tube is controlled to be turned on for a period of time and then turned off for a period of time, and the cycle is repeated. The advantage of this method is that when the battery is charged through an external circuit, the generation of ions inside the battery requires a certain response time. If it is charged continuously, its capacity potential may be reduced. After charging for a period of time, adding a shutdown time can allow the polar ions of the battery to diffuse and allow the battery to have a "digestion" time, which will greatly improve the battery utilization rate and improve the charging effect.

- Does lithium iron phosphate battery need a protection board? The correct way to charge lithium iron phosphate battery

- How are diodes made using semiconductors?

- Advantages and disadvantages of organic semiconductors, the conductive mechanism of organic semiconductors

- Why Do Amplifier Fuses Blow? How Do You Prevent Amplifier Fuses from Blowing?

- Diode-based clipping circuit

- How to build a drag racing timer circuit using a 7-segment display and discrete components

- Make a flameless electronic candle using simple electronics and LEDs

- Introduction of TDA4863J/4863AJ TV field scanning IC

- Experimental circuit based on 4040 binary adder counter

- Circuit diagram of a differential amplifier circuit

- Simple nickel-cadmium battery charging device

- Nickel-cadmium battery charging IC (S1633A) circuit

- Nickel cadmium battery charge controller ATC105 circuit 02

- Lithium-ion battery charging control module PS1719 circuit

- Application of battery charge controller MAX2003 02

- 9V nickel-cadmium battery charging circuit diagram

- Circuit diagram of battery charging using a step-down switching power supply connected with LT1074

- Nickel-cadmium battery charging circuit 13 examples 2

- Nickel-cadmium battery charging circuit 13 examples 1

- Cadmium bromine battery charging circuit

京公网安备 11010802033920号

京公网安备 11010802033920号