Causes of PCB deformation How to prevent circuit board bending and warping

Source: InternetPublisher:萌面大虾 Keywords: printed circuit board circuit board PCB Updated: 2025/01/03

When printed circuit boards undergo reflow soldering, most of them are prone to circuit board bending and warping. In severe cases, it may even cause components such as empty solder joints and tombstoning. How to overcome it?

1. Deformation of circuit board

In the automated surface mount line, if the circuit board is not flat, it will lead to inaccurate positioning, components cannot be inserted or installed on the holes and surface mount pads of the board, and even the automatic insertion machine will be damaged. The circuit board on which the components are installed is bent after soldering, and the component feet are difficult to cut neatly. The motherboard cannot be installed on the socket inside the chassis or machine. Therefore, the assembly plant encounters circuit board warping. This is very annoying. The current surface mount technology is developing in the direction of high precision, high speed, and intelligence, and higher flatness requirements are put forward for circuit boards that accommodate various components. In the IPC standard, it is specifically pointed out that the allowable deformation of circuit boards with surface mount devices is 0.75%, and the allowable deformation of PCB boards without surface mount is 1.5%. In order to meet the requirements of high-precision and high-speed mounting, some electronic assembly manufacturers have stricter requirements on the amount of deformation. PCB boards are composed of materials such as copper foil, resin, and glass cloth. The physical and chemical properties of each material are different. After pressing together, thermal stress will inevitably occur, resulting in deformation. At the same time, during the PCB processing process, it will undergo high temperature, mechanical cutting, wet processing, and so on. Various processes also have an important impact on the deformation of the board. In short, the reasons for PCB board deformation are complex and diverse. How to reduce or eliminate the deformation caused by different material properties or processing has become one of the complex issues faced by PCB board manufacturers.

2. Deformation

Cause Analysis The deformation of PCB boards needs to be studied from several aspects such as materials, structure, pattern distribution, processing technology, etc. This article will analyze and explain various reasons and improvement methods that may cause deformation. Uneven copper surface area on the circuit board will aggravate the bending and warping of the circuit board. Usually, a large area of copper foil is designed on the circuit board for grounding, and sometimes the Vcc layer will also have a large area of copper foil. When these large areas of copper foil are unevenly distributed on the same circuit board, it will cause uneven heat absorption and heat dissipation. Of course, the circuit board will also expand and contract when cold. If expansion and contraction cannot be carried out at the same time, different stresses and deformations will be caused. At this time, if the temperature of the board has reached the upper limit of the Tg value, the board will open and begin to soften, resulting in deformation. The connection points (vias, through holes) of each layer on the circuit board will limit the expansion and contraction of the circuit board. Today's circuit boards are mostly multi-layer boards, with rivet-like connection points (vias) between layers. The connection points are divided into through holes, blind holes and buried holes. Where there are connection points, the expansion and contraction effects of the board will be limited, and it will also indirectly cause the circuit board to bend and warp. The weight of the board will cause the board to sag and deform. Usually, the reflow oven will use a chain to drive the circuit board forward in the reflow oven, that is, the two sides of the board are used as fulcrums to support the entire board. If there are heavy parts on the board, or if the size of the board is too large, it will show a sag in the middle due to the number of the board itself, causing the board to bend.Video of the depth of V-Cut and the connecting rodBasically, V-Cut is the culprit for destroying the structure of the circuit board. Since V-Cut cuts a groove on the original large plate, the position of V-Cut is prone to deformation.

2.1 Material, structure, and pattern on the board

Analysis of the influence of deformation PCB board is formed by pressing the core board and prepreg and outer copper foil. The core board and copper foil are heated and deformed during pressing. The amount of deformation depends on the coefficient of thermal expansion (CTE) of the two materials. The coefficient of thermal expansion (CTE) of copper foil is about, while the Z direction CTE of ordinary FR-4 substrate below Tg point; above TG point is (250~350)X10-6, while the X direction CTE is due to the presence of glass cloth, which is generally similar to copper foil. TG point precautions: When the temperature of high Tg printed board rises to a certain area, the substrate will change from "glass-like" to "rubber-like", and the temperature at this time is called the glass transition temperature (Tg) of the board. That is, Tg is the temperature (°C) at which the substrate maintains rigidity. In other words, ordinary PCB board substrate materials will not only soften, deform, melt, etc. at high temperatures. At the same time, it also manifests as a sharp drop in mechanical and electrical properties. Generally speaking, Tg of board is greater than 130 degrees, high Tg is generally greater than 170 degrees, and medium Tg is greater than about 150 degrees. Usually PCB printed boards with Tg ≥ 170°C are called high Tg printed boards. With the increase of substrate Tg, the heat resistance, moisture resistance, chemical resistance, stability and other characteristics of the printed board will be improved and enhanced. The higher the TG value, the better the temperature resistance of the circuit board, especially in lead-free processes, high Tg applications are more common. High Tg refers to high heat resistance. With the rapid development of the electronics industry, especially electronic products represented by computers, the development of high functionality and high multi-layer requires that the PCB board substrate material has higher heat resistance as an important guarantee. The emergence and development of representative high-density mounting technology has made PCB boards increasingly inseparable from small apertures, fine lines, thinning, etc.

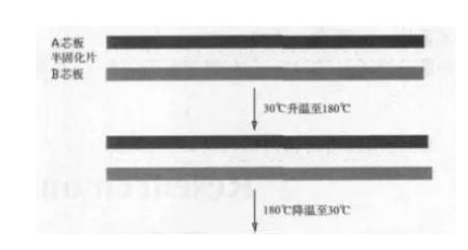

The support of high heat resistance of the substrate. Therefore, the difference between general FR-4 and high Tg FR-4 lies in the mechanical strength, dimensional stability, adhesion, water absorption and thermal decomposition of the material in a hot state, especially when heated after moisture absorption. There are differences in various conditions such as expansion. High Tg products are significantly better than ordinary PCB board substrate materials. Due to the difference between the pattern distribution and the thickness or material properties of the core board, the expansion of the core board with the inner pattern is different. When the pattern distribution is different from the thickness or material properties of the core board, it will be different. When the pattern distribution is relatively uniform, the material type is the same. It will deform. The asymmetric or uneven pattern distribution of the PCB board laminate structure will cause the CTE of different core boards to be very different, resulting in deformation during the lamination process. The deformation mechanism can be explained by the following principle. Assume that two core boards with large CTE differences are pressed together by prepreg, where the CTE of core board A is 1.5x10-5/degree Celsius and the length of the core board is 1000mm. The pressing process is used as a prepreg for the bonding sheet, and the two core boards are bonded together through three stages of softening, flowing and filling patterns and curing. At this time, the deformation of the two core boards is △LA=(180 degrees Celsius ~ 30 degrees Celsius) x1.5x10-5m/degree Celsius X1000mm=2.25mm; △LB=(180 degrees Celsius ~ 30 degrees Celsius) X2.5X10-5m/degree Celsius X1000mm=3.75mm. In the free state, the two core boards are long and short, do not interfere with each other, and have not yet deformed. During the pressing process, it will be kept at high temperature for a period of time until the semi-curing is completely cured. At this time, the resin becomes a cured state and cannot flow at will. The two core boards are combined together. When the temperature drops, if there is no interlayer resin bonding, the core board will return to its original length without deformation. The upper two core boards are bonded by the curing resin at high temperature and cannot shrink at will during the cooling process. A company RE board should shrink by 3.75 mm. In fact, when the shrinkage rate is greater than 2.25mm,

It is hindered by the A core board. The forces between the two core boards are balanced, the B core board cannot shrink to 3.75mm, and the A core board shrinks more than 2.25mm, making the entire board face the B core board.

2.2 Deformation caused during PCB processing

The reasons for deformation during the process are very complicated and can be divided into two types of stress: thermal stress and mechanical stress. Among them, thermal stress is mainly generated during the pressing process, and mechanical stress is mainly generated during the stacking, handling and baking of the board. The following is a brief discussion in the order of the process. Incoming copper clad laminates: Copper clad laminates are all double-sided, symmetrical in structure, and have no graphics. The CTE of copper foil and glass cloth are almost the same, so there is almost no deformation caused by CTE differences during the pressing process. However, the size of the copper clad press is large, and there is a temperature difference in different areas of the hot plate, which will cause the resin curing speed and degree in different areas during the pressing process to be slightly different, and the temperature rise is different. There are also great differences in dynamic viscosity at different speeds, so local stress will also be generated due to differences in the curing process. Usually, this stress will remain balanced after pressing, but will gradually release and deform in subsequent processing.

Pressing: The PCB board pressing process is the main process that generates thermal stress. The deformation caused by different materials or structures is shown in the analysis in the previous section. Similar to the pressing of copper clad laminates, local stress caused by differences in the curing process will also appear. PCB boards have more thermal stress than copper clad laminates because of thicker thickness, diversified pattern distribution, and more prepreg. The stress in the PCB board is released during the subsequent drilling, molding, or baking process, causing the circuit board to deform.

Baking process of solder mask, characters, etc.: Since solder mask ink cannot be stacked together when curing, the PCB board will be placed in a rack for curing. The temperature of the solder mask is about 150°C, just exceeding the Tg point of medium and low Tg materials. The resin above the Tg point has high elasticity, and the board is easily deformed under its own weight or the strong wind of the oven.

Hot air solder leveling: The temperature of the tin furnace is 225 degrees Celsius to 265 degrees Celsius, and the hot air solder leveling time for ordinary boards is 3S-6S. The temperature of the hot air is 280 degrees Celsius to 300 degrees Celsius. After the solder is leveled, the circuit board enters the tin furnace from room temperature, and is washed with room temperature post-treatment water within two minutes after leaving the furnace. The entire hot air solder leveling process is a process of sudden heating and cooling.

Due to the different materials and uneven structures of the circuit boards, thermal stress will inevitably be generated during the process, resulting in microscopic strain and overall deformation warping area.

Storage: PCB boards are generally firmly inserted into shelves during storage at the semi-finished stage, the tightness of the shelves is not properly adjusted, or the stacking of boards during storage will cause mechanical deformation of the boards. Especially for thin boards below 2.0mm, the impact is more serious. In addition to the above factors, there are many factors that affect the deformation of PCB boards.

3. Improvement measures

So how do we prevent the board from bending and warping when it goes through the reflow oven?

1) Reduce the effect of temperature on sheet stress: Since temperature is the main stress of the sheet, as long as the temperature of the reflow oven is reduced or the heating and cooling speed of the sheet in the reflow oven is slowed down, the bending and warping of the sheet can be greatly reduced. But there may be other side effects.

2) Use high Tg board: Tg is the glass transition temperature, which is the temperature at which the material changes from glass to rubber. The lower the Tg value, the faster the board starts to soften after entering the reflow oven. And the time it takes to become a soft rubber state

It will be longer, and of course the deformation of the board will be more serious. Using a higher Tg sheet will increase its stress and deformation, but the price of the material is relatively high.

3) Increase the thickness of the circuit board: In order to achieve the purpose of making many electronic products lighter and thinner, the thickness of the circuit board has been left at 1.0mm, 0.8mm or even 0.6mm. This thickness should keep the board from deforming after the reflow oven, which is really difficult. It is recommended that if there is no requirement for lightness and thinness, a board with a thickness of 1.6mm can be used, which can greatly reduce the risk of board bending and deformation.

4) Reduce the size of the circuit board and reduce the number of panels: Since most reflow ovens use chains to drive the circuit board forward, the larger circuit board size will sag in the reflow oven due to its own weight, so try to put the long side of the circuit board as one side of the board on the chain of the reflow oven, so as to reduce the sag and deformation caused by the weight of the circuit board itself, and put the circuit boards together. The reduction in quantity is also based on this reason, that is, when passing through the furnace, try to use the narrow side perpendicular to the direction of the furnace to achieve the amount of sag deformation.

5) Use a furnace plate clamp: If the above method is difficult to achieve, use a furnace plate to reduce the deformation. The reason why the furnace plate can reduce the bending of the board is that no matter it is thermal expansion or contraction, it is hoped that the furnace plate can hold the circuit board and wait until the temperature of the circuit board is lower than the Tg value before hardening, so that the size of the garden can be maintained. If a single-layer support. The tray cannot reduce the deformation of the circuit board, it is necessary to add a layer of cover and clamp the circuit board with the upper and lower trays, thereby greatly reducing

The problem of circuit boards deforming when passing through the reflow oven. However, oven trays are very expensive and require manual placement and recovery of trays.

6) Use real connections and punch holes instead of V-Cut sub-boards: Since V-Cut will destroy the structural strength of the circuit board between the boards, try not to use V-Cut sub-boards, or reduce the depth of V-Cut. PCB board optimization. Production engineering: The deformation of the board affected by different materials will be counted into the defect rate of different material boards. Deformation of low Tg materials. The sinking rate is higher than that of high Tg materials. The high Tg materials listed in the above table are all filler-shaped materials, and the CTE is smaller than that of low Tg materials. At the same time, during the processing after pressing, the baking temperature is 150 degrees Celsius. The impact will definitely be greater than that of medium and high Tg materials. Engineering design should try to avoid structural asymmetry, material asymmetry, and graphic asymmetry design to reduce deformation. At the same time, during the research process, it was also found that the core board direct laminated structure is more prone to deformation than the copper foil laminated structure. In engineering design, the frame form of the puzzle board also has a greater impact on deformation.

Generally speaking, PCB factories have continuous large copper frames and discontinuous copper point or copper block frames, and there are also different differences. The reason for the different deformation of the two frame forms is that the continuous copper frame has high strength and relatively large rigidity during the pressing and splicing process, which makes it difficult to release the residual stress in the board. After the shape processing, the release is concentrated, resulting in more serious deformation. The discontinuous copper point frame gradually releases stress during the pressing and subsequent processing, and the deformation of the single board is small after forming. The above are some of the influencing factors that may be involved in engineering design. At that time, it can be used flexibly. It can reduce the impact of deformation caused by design.

3.3 Compression study

The effect of pressure on deformation is very important. Reasonable parameter settings, press selection and stacking methods can effectively reduce stress. For general panels with symmetrical structures, it is generally necessary to pay attention to the symmetrical stacking of panels when pressing, and to symmetrically place auxiliary tools such as tool panels and buffer materials. At the same time, choosing a hot and cold integrated press to press is also significantly helpful in reducing thermal stress. In order for the hot and cold press to transfer the sheet to the cold press at high temperature (above GT temperature), the pressure loss and rapid cooling of the material above the Tg point will cause rapid release and deformation of thermal stress, while the hot and cold integrated press can achieve cooling at the end of hot pressing to avoid pressure loss of the board at high temperature. At the same time, for the special needs of customers, some sheets with asymmetric materials or structures will inevitably appear. At this time, the deformation caused by different CTEs analyzed in the previous article will be very obvious. For this problem, we can try to solve this problem using an asymmetric stacking method. The principle is to use the asymmetric placement of buffer materials to reach the PCB board. The heating speed of both sides is different, which affects the expansion and contraction of different CTE core cypresses during the heating and cooling stages to solve the problem of inconsistent deformation. Yes, this is the test result on a certain structural asymmetric board of our company. Through asymmetric stacking, adding a post-curing process after pressing, and leveling before shipment, the board finally meets the customer's 2.0mm requirement.

3.4 Other production processes

In the PCB board production process, in addition to pressing, there are several high-temperature processing processes for solder mask, characterization and hot air leveling. Among them, the temperature of solder mask and characterization after baking the board is 150 degrees Celsius. As mentioned above, this temperature is in the ordinary Tg material. Above the Tg point, the material is in a high elastic state and is easily deformed under external force. Therefore, avoid stacking the boards to prevent the lower board from bending when drying the boards, and ensure that the boards are in the direction of the workpiece parallel to the blowing direction. During the hot air leveling process, it is necessary to ensure that the board is placed in the tin furnace and cooled for more than 30 seconds to avoid sudden cold deformation after cold water washing after high-temperature post-treatment. In addition to the production process, the storage of PCB boards at each station also has a certain influence on deformation. In some manufacturers, due to the large number of products to be produced and the small space, multiple boards are stacked together for storage. This will also cause the circuit board to deform due to external force. Since the PCB board also has a certain plasticity, these deformations will not be 100% restored in the subsequent leveling process.

- Analysis of the flow direction of transistor current

- An article explains the working principle of the Wheatstone bridge

- What are the main types of resistors? Detailed explanation of the functions and uses of resistors

- Advantages and disadvantages of organic semiconductors, the conductive mechanism of organic semiconductors

- What are the classifications of filters?

- How do you calculate the value of capacitors in series? Why use capacitors in series?

- How does RCCB work?

- Why use PWM? What are its advantages?

- Simple LED advertising light circuit

- Circuit diagram of a differential amplifier circuit

- AD power supply circuit design experience, worth collecting

- How to design a switching power supply?

- What is a power distribution system and what exactly does power integrity mean?

- A brief analysis of the working principle of bipolar power supply providing current

- Do you know the advantages of laying copper on the bottom layer of PCB?

- Do you know PCB design tips to improve the electromagnetic compatibility of circuit boards?

- Comparison between hard board PCB and soft board FPC

- Crystal oscillator PCB design considerations

- PCB circuit board heat dissipation method

- PCB layout and routing rules analysis

京公网安备 11010802033920号

京公网安备 11010802033920号