WBR3 is a low-power embedded Wi-Fi+BLE module developed by Tuya Smart. It consists of a highly integrated wireless radio frequency chip RTL8720CF, with built-in Wi-Fi network protocol stack and rich library functions.

WBR3 includes low-power KM4 MCU, WLAN MAC, 1T1R WLAN, with a maximum frequency of 100MHz, built-in 256K SRAM, built-in 2Mbyte flash and rich peripheral resources in the chip.

WBR3 is an RTOS platform that integrates all Wi-Fi MAC and TCP/IP protocol function libraries. Users can develop embedded Wi-Fi products that meet their own needs based on these.

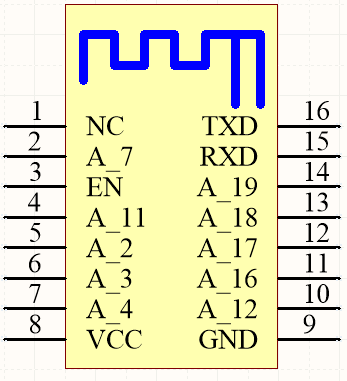

WBR3 schematic pin correspondence diagram

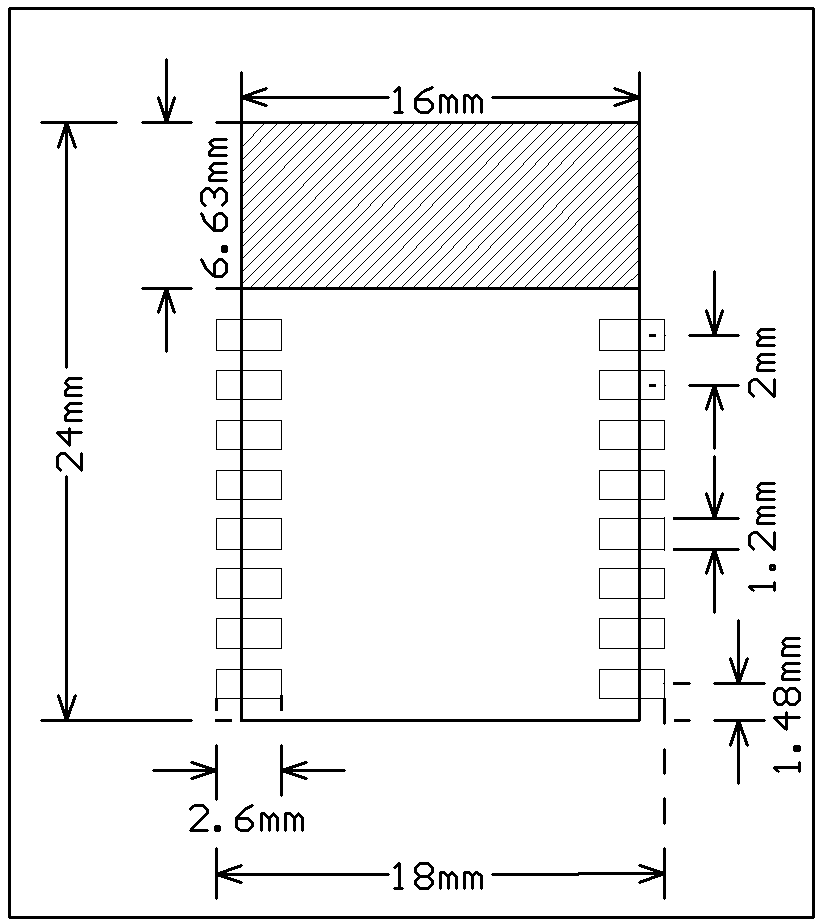

WBR3 PCB package

Support 5V1A output

1) AC input voltage range 90-264Vac

2) DC output 5V/1.0A

3) Meet the requirements of Energy Star 2.0 and Level 5 energy efficiency with sufficient margin (board end data)

(The measured average efficiency is above 73.50% at the PCB board end, and the Energy Star 2.0 standard is 68.17%)

4) No-load standby power consumption is less than 100mW (actual measurement: 70mW@230Vac)

5) Meet the requirements of EMI EN55022 Class B with sufficient margin

6) The maximum output ripple is less than 120mVP-P

7) Mass production of the system ensures that the output voltage accuracy is within ±5% and the output current accuracy is within ±5%.

8) Self-restoring short circuit protection and open loop protection

5. The relay output circuit uses a stable and mature triode to drive two 16a high-power relays.

Wiring instruction diagram

I originally had an idea to change the garage door at home into a mobile phone smart remote control. This time there happened to be an EDA IoT practical training camp event. After more than 10 days of hard work, drawing circuit boards, soldering circuit boards, and constantly rewriting the code, I finally succeeded. I am so excited. Please give me more suggestions. We will work hard to make practical products, and the next step will be mass production. Thank you Lichuang and Tuya for supporting this event! We will carry out more activities like this in the future.

All reference designs on this site are sourced from major semiconductor manufacturers or collected online for learning and research. The copyright belongs to the semiconductor manufacturer or the original author. If you believe that the reference design of this site infringes upon your relevant rights and interests, please send us a rights notice. As a neutral platform service provider, we will take measures to delete the relevant content in accordance with relevant laws after receiving the relevant notice from the rights holder. Please send relevant notifications to email: bbs_service@eeworld.com.cn.

It is your responsibility to test the circuit yourself and determine its suitability for you. EEWorld will not be liable for direct, indirect, special, incidental, consequential or punitive damages arising from any cause or anything connected to any reference design used.

Supported by EEWorld Datasheet