Programmable logic controllers (PLCs) and distributed control systems (DCS) use more digital input signals than any other combination of input signal types. Parallel connection of industrial digital input cables to a PLC is not only expensive, but also tends to create a rat's nest of wiring that is difficult to maintain. Fieldbus greatly improves this situation by moving the I/O interface from the PLC to a remote I/O hub near the on-site sensors . However, the lack of a single, universally accepted fieldbus also creates confusion, training challenges, high costs, and compatibility issues between devices1 .

IO-Link is the first open, fieldbus-agnostic, low-cost, point-to-point serial communication bus protocol for communicating with sensors and actuators that has been adopted as an international standard (IEC 61131-9) 2 . IO-Link finally standardized the interoperability of industrial equipment around the world. IO-Link can be operated directly from a PLC or integrated into any standard fieldbus, making it quickly becoming the de facto standard for communicating with smart devices such as the MAXREFDES36#.

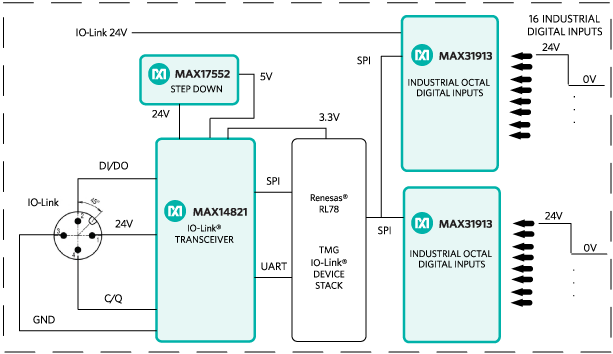

MAXREFDES36# is a 16-channel IO-Link digital input hub mounted on a small 53.75mm x 72mm printed circuit board (PCB). Maxim Integrated and Technologie Management Gruppe Technologie und Engineering (TMG TE) collaborated to design MAXREFDES36# as a digital input hub reference design compatible with version 1.1/1.0 of the IO-Link protocol . The MAXREFDES36# design includes industry-standard Maxim Integrated IO-Link device transceiver ( MAX14821 ); high-efficiency, high-voltage, step-down converter ( MAX17552 ); Renesas® ultra -low-power, 16-bit microcontroller (RL78), Uses TMG TE's IO-Link device stack and two Maxim Integrated digital input serializers ( MAX31913 ). Figure 1 shows the system block diagram.

Figure 1. MAXREFDES36# reference design block diagram.

DIN rail design

IEC 61131-9

Compatible with IO-Link versions 1.1 and 1.0

On-chip 8:1 serialization

Fault monitoring

Field powered LED driver

Small size

Low power consumption

low cost

PLC digital input module

production line

Conveyor system

robot

process control and automation

automated industry

PLC and DCS systems

All reference designs on this site are sourced from major semiconductor manufacturers or collected online for learning and research. The copyright belongs to the semiconductor manufacturer or the original author. If you believe that the reference design of this site infringes upon your relevant rights and interests, please send us a rights notice. As a neutral platform service provider, we will take measures to delete the relevant content in accordance with relevant laws after receiving the relevant notice from the rights holder. Please send relevant notifications to email: bbs_service@eeworld.com.cn.

It is your responsibility to test the circuit yourself and determine its suitability for you. EEWorld will not be liable for direct, indirect, special, incidental, consequential or punitive damages arising from any cause or anything connected to any reference design used.

Supported by EEWorld Datasheet